Indian Stone Patios and Drives for Manchester.

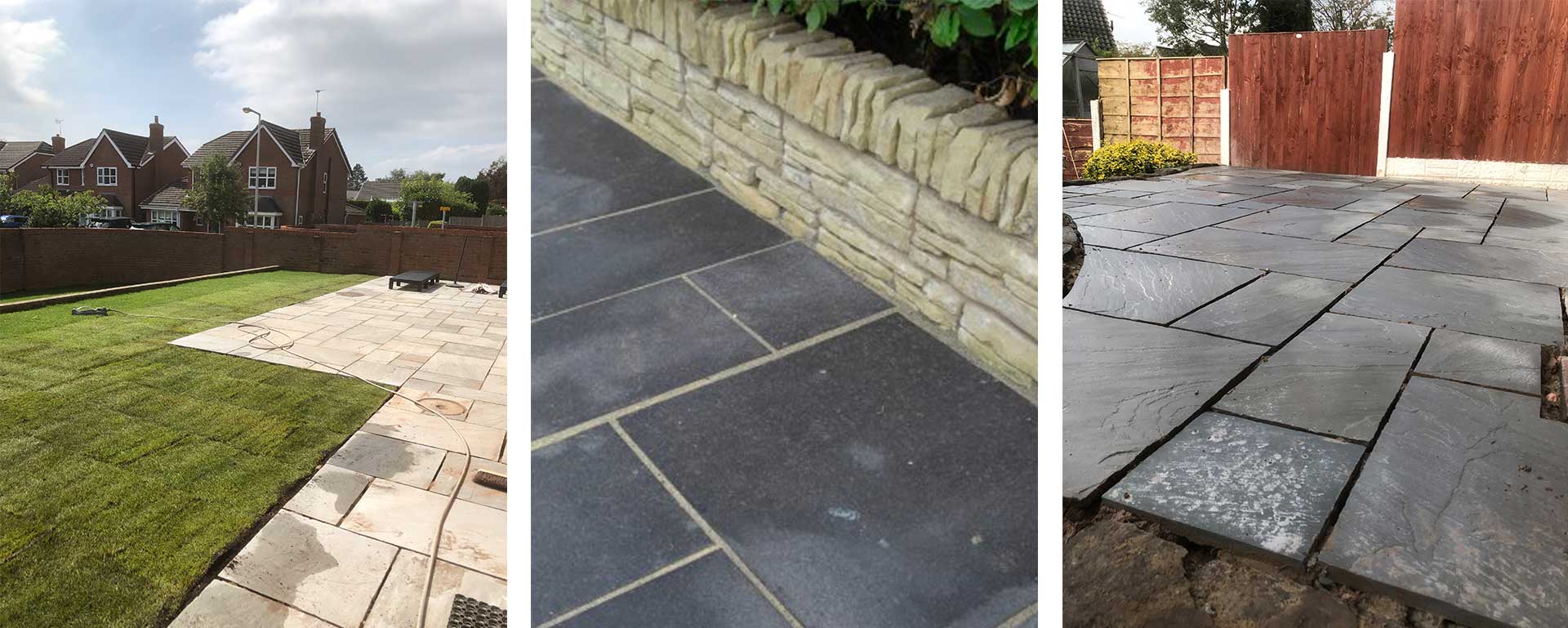

Renownd for it’s range of colours and high quality finish, Indian Stone is a popular choice in Manchester.

By far our most popular patio product, we have installed patios using various colour of Indian Stone all over Greater Manchester from Didsbury and Timperley right the way through to Whitefield.

FREE NO-OBLIGATION QUOTE

Enter your details and we’ll call you right back

Indian Stone Colours

What is Indian Stone Paving?

With a rise to popularity within in 90’s, Indian stone paving is a special type of stone which is 100% natural and often used on patios and paths because of the clean and high quality finish.

As the name suggests this stunning stone is imported directly from India, taken directly from the rocks these slabs are considered to be some of the best on the market by the Landscaping industry. As they are 100% natural each slab is totally unique, this means that no one else is the world will have a patio exactly like yours!

ENQUIRE FOR A FREE QUOTE

Fill in the form below to schedule a FREE quote.

What is the difference between hand-cut and sawn Indian Stone?

Hand Cut

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed sit amet ultricies justo. Donec congue ex risus, sit amet fermentum sapien efficitur sed. Nulla consectetur, arcu eu consectetur ultrices, eros sem pellentesque dui, vitae vestibulum est arcu nec ipsum. Quisque condimentum,

Sawn

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed sit amet ultricies justo. Donec congue ex risus, sit amet fermentum sapien efficitur sed. Nulla consectetur, arcu eu consectetur ultrices, eros sem pellentesque dui, vitae vestibulum est arcu nec ipsum. Quisque condimentum,

Is natural stone sustainable?

Natural Stone is the most sustainable building material, as resources of stone on earth are vast, plentiful and date back billions of years. Although the re-generation of stone is not as readily visible as the re-generation of trees, it is a continuous process with natural stone having an enduring life-cycle.

What is calibrated Indian Stone?

Calibrated slabs have been cut to a specific thickness. Today the majority of stone paving slabs produced are calibrated (depth measurement) at 18-22mm thick, whereas the norm 10 years ago used to be 25-35mm thick which some businesses still prefer.

How hardwearing is Indian Stone?

Good quality sandstone is tough. It’s frost resistant, very strong and doesn’t green up with moss and algae as quickly as some other natural stone paving. And why? It’s all to do with where it comes from.

The toughest quartzitic sandstone is quarried from older, deeper rock strata that have been compressed over millions of years. I t’s dense and hard; it takes longer to cut and process, and it’s got a lower water content than newer, softer, more porous (and cheaper) rock.

How to clean and Indian Stone Patio

Regular maintenance and cleaning of your new natural stone area is recommended to keep the area looking its best. There are various cleaners available on the market. Some cleaners specialise in dealing with specific types of stains, and others are general cleaners.

We recommend you brush your paved area regularly as well as cleaning it from time to time. Ensure you use a soft bristled brush when sweeping your paved area, as tougher wire brushes could scratch the stone.

Brushing the stone will provide the safest option for keeping the stone clean, using water with a neutral pH soap or detergent should be sufficient for routine maintenance. Power washers may be too powerful and cause damage to the surface of the stone and the mortar joints.

If they are used do so with great care and at your own risk. Strongly acidic or alkaline cleaners may also cause severe damage to the stone and create other environmental problems. Always check the instructions on the product before using it to clean your natural stone.

Before using any cleaning products on your natural stone test a small, discreet area of paving first to make sure you are happy with the result.

Should I seal my stone?

There are many sealers available on the market that offer different finishes. Natural stone does not have to be sealed and so sealing is a personal choice. Some sealers are designed to affect the appearance of the stone, such as leaving a satin or invisible finish. Sealing can help delay the absorption of liquids also.

An important factor to consider if deciding to seal your stone is whether or not the sealer is breathable because if it is not then mobile salts in solution can be trapped beneath the surface. An example of a potential problem caused by the use of the wrong sealer would be where efflorescence develops but the sealer prevents salts from exiting through the sealed surface. The build-up of the salts not only can result in a difficult to remove stain but can often cause disruption and breakdown of the surface itself.

With unbreathable sealants, merchants will normally recommend that you wait three months before sealing your recently paved area, to allow for efflorescence to appear. This can then be washed off before sealing.

If using a breathable sealant, the paved area can usually be sealed straight after installation, but always check with the product manufacturer. If you make the decision to use a sealer on your natural stone, test the product on a small, discreet area first, to make sure you are happy with the result.

ENQUIRE FOR A FREE QUOTE

Fill in the form below to schedule a FREE quote.

Incorrect methods often used when laying Indian Stone.

Spot Bedding

Spot bedding is where the installer leaves spaces beneath the flags, rather than laying the flagstone on a full mortar bed.

This method can lead to reflective staining, which appears as unsightly circular marks on the surface of the stone. The marks can appear days after installation or a few months after the paving has been laid. We would always recommend laying a flagstone on a full mortar bed.

Once reflective staining occurs there isn’t much that can be done to reverse the effects, as it is due to the incorrect installation of the stone

Butt Jointing

This occurs when no joint space is left between adjacent paving units, the stone is effectively ‘butted’ together and this can cause a number of issues once the stone is laid.

Spalling, where the stone starts to chip due to direct contact with surrounding paving units is often a result of butt jointing. Butt jointing also promotes delamination of some types of stone. This is where the surface of the stone starts to chip and flake off. Although delamination can occur naturally, butt jointing encourages this occurrence.

We would recommend a joint width of 10-12mm between flagstones and 2-5mm between block paving.

FREE NO-OBLIGATION QUOTE

Enter your details and we’ll call you right back

Call 07762099804

Stunning Landscapes

25 Hamer Street,

Bury,

Manchester,

M262RS